Straw bale building was first developed in America during the 1800’s and is a technique that is rapidly gaining popularity today. Building with straw bales can be easy, cheap and fun. It is also a way to make a superbly energy efficient building.

Straw bale building was first developed in America during the 1800’s and is a technique that is rapidly gaining popularity today. Building with straw bales can be easy, cheap and fun. It is also a way to make a superbly energy efficient building.

Conventional construction methods use vast amounts of energy, producing over half of all greenhouse gasses and involve toxic and pollluting materials. By contrast, straw is a natural material of which we currently produce an excess sufficient to build half a million homes each year. Straw is highly insulative, giving heat savings of up to 75% compared to a conventional modern house. Straw bale walls have excellent load bearing capacity and are quite suitable for two storey houses with all mod-cons.

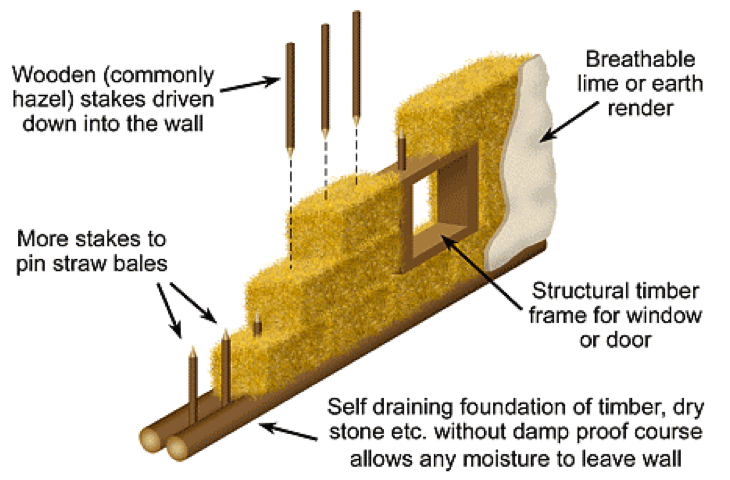

Straw bales can be used either for load bearing walls (which hold up a roof or next storey) or infill (with separate support eg. a timber frame). In either case the bales are stacked like giant bricks and secured to each other with wooden stakes. These stakes can be hammered through the bales or tied in pairs on opposite sides of the wall. When laying bales on a wall the straws should run horizontally, not vertically otherwise the bales will tend to sink into each other.

It is important that the bales be allowed to breathe to prevent accumulation of moisture and rotting. The bale wall should NOT be placed directly on a (plastic) dampproof course, this can cause accumulation of moisture at the bottom of the wall. Instead any moisture should be allowed to leave the bottom of the wall. An 18″ high dry-stone wall base (stem wall) will do this job very well if you are building on the ground. If you are building on a platform / stilts a timber base is usually more appropriate.

Straw bale walls are most commonly rendered. A breathable render can be made from a mix of sand and either lime or clay. A lime render is more durable and hence suitable for exterior use in wet climates. I personally quite like to use lime render inside as well as it is strong and sets quickly without cracking. A clay render can usually be made using local clay soil (better) though it may need sponging over daily for a week or two after application to fill any cracks.

Either of these renders can be finished with limewash and / or a natural breathable paint. I like limewash and breathable emulsion indoors and an annually repeated limewash outdoors (a very quick job). Note that cement / gypsum render should not be used as they don’t breathe and can lead to accumulation of moisture in the wall.